The automatic peanut butter production line mainly comprises the roasting machine, peeling machine, grinding machine, storing, mixing, vacuum tanks, and packing machine. The peanut butter processing line is suitable for processing peanuts, almonds, cashew nuts, cocoa beans, sesame, and other nuts or beans. The whole series of peanut butter making machines characterizes high mechanization, high productivity, and high-quality superfine product.

As a professional and experienced peanut butter processing equipment manufacturer, we offer semi-automatic and fully automatic peanut butter processing machinery with small, medium, and large outputs reaching from 100-1000kg/h. We have delivered our peanut butter machinery to a large number of countries across the world.

Types of peanut butter production lines

As a peanut butter machine manufacturer, we have produced semi-automatic and fully automatic peanut butter production lines to meet the different demands of customers.

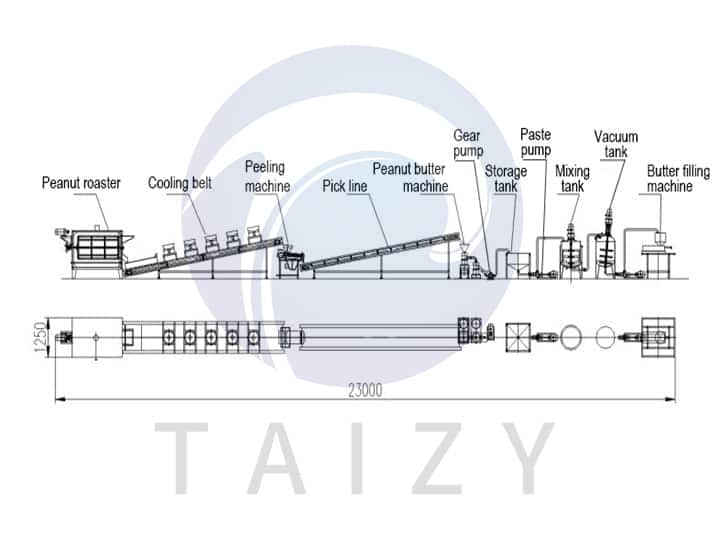

1. Semi-automatic peanut butter processing equipment

Machine list: peanut roasting machine (a supporting conveyor shall be added in front of a large-capacity roaster), cooling machine, peeling machine, selecting conveyor, lifting machine, grinding machine, storing, mixing, and vacuum tanks, and semi-automatic filling machine.

Production Line Structure

- Roasting Machine

- Cooling Belt

- Peeling Machine

- Picking Line

- Grinding Machine

- Gear Pump

- Storage Tank

- Paste Pump

- Mixing Tank

- Vacuum Tank

- Semi-Automatic Filling Machine

Video (3D version)

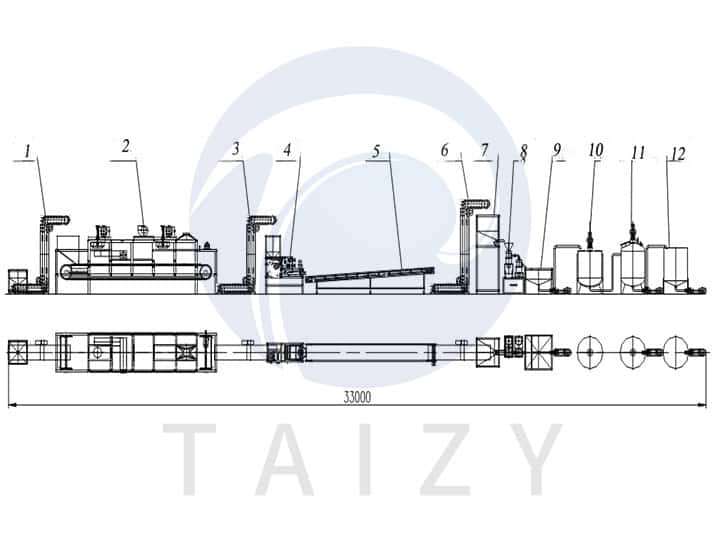

2. Fully automatic peanut butter production line

Machine list: continuous roasting and cooling machine, peanut peeling machine, selecting conveyor, lifting machine, grinding machine, storage, mixing and vacuum tanks, bottle unscrambler, automatic filling machine, closing machine, rotary capping machine, and labeling machine.

Production line structure

- lifting machine

- chain roasting and cooling machine

- lifting machine

- peanut peeling and split machine

- selecting conveyor

- lifting machine

- storage bin

- peanut grinding machine

- storage slot

- mixing tank

- vacuum tank

- storage tank

Video (3D version)

Video: automatic peanut butter manufacturing line in factory

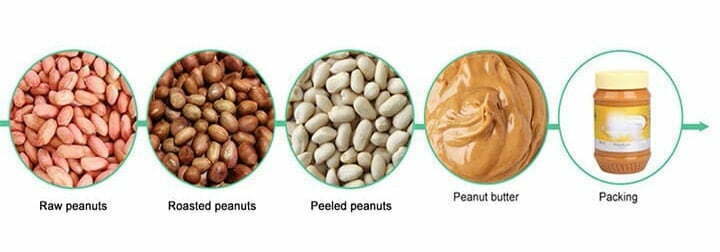

Peanut butter processing procedures

The main procedures of the automatic peanut butter making machines: Roasting → Cooling → Peeling → Selecting → Lifting → Grinding → Storing → Mixing → Degassing → Filling

Step 1 Pour raw peanut kernels into the hopper of the roaster machine for baking for a while until the red skin of the peanuts becomes crisp. The roasting machine rolls roasted peanuts out automatically.

Attention: Don’t Over-Bake. In case the taste of peanut butter is affected.

Step 2 Then peanuts are transported to the cooling belt and tiled for cooling to maintain and keep the original flavor of the peanuts.

Step 3 Cooled peanuts are peeled by the peeling machine to remove the red skins. And unqualified or other materials are excluded from the selection belt.

Step 4 Grinding machine (colloid mill) crushes peanut kernels, and the peanut butter is then stored in storage tanks.

Step 5 The peanut butter is sent to the storage tank and goes through the steel pipe to arrive in the mixing tank. Here, butter is added with seasonings to make it tastier.

Step 6 Vacuum tank eliminates air. In this way, the shelf life of peanut butter is extended.

Step 7 The final peanut butter is filled in bottles for selling.

Main Machines of Peanut Butter Production Line

Roaster → Peeling Machine → Selecting Belt → Grinding Machine → Storing Tank → Mixing Tank → Vacuum Tank → Filling Machine

Pretreatment equipment

To get clean peanut kernels, it is often required to use a peanut sheller machine and a peanut destoner machine at first in the peanut butter production line.

A peanut sheller machine is used to remove the shells of peanuts with high efficiency.

A peanut destoner is to clear up the peanut kernels by eliminating the impurities, like stone or dirt.

Peanut roasting machine

Type 1: rotary drum peanut roaster

Thispeanuts roasting machine is mainly used for baking peanut kernels. It adopts the advanced structure of the drum, which is cutting-edge technology. The heating source can be electricity or gas. A thermostat is installed to adjust the temperature.

The temperature can reach 240-260 Celsius degrees in an electricity-heated roaster, 220-240 in a gas-heated model. The roasting time can be set.

Working Principle

Put raw materials into the inlet, and the drum rotates continuously. In the process, roasted food moves up and down, left and right, back and forth, and is fully stereoscopic. Thus, the drum roasting machine heats peanuts uniformly.

When the time is up, the peanut roaster machine discharges roasted nuts. This machine is applied in baking peanuts, almonds, sesame, and other nuts.

Technical Parameter

| Model | TZ-1 | TZ-2 | TZ-3 | TZ-4 | TZ-5 |

| Capacity (kg/h) | 50 | 100 | 200 | 300-350 | 500-600 |

| Voltage (V) | 380 | 380 | 380 | 380 | 380 |

| Transmission power (kw) | 0.75 | 1.1 | 2.2 | 3.3 | 5.5 |

| Dimension (mm) | 2300x1000x1350 | 2900x1400x1650 | 2900x2100x1650 | 3000x2900x1650mm | 4700x2900x1650 |

| Gas consumption (kg) | 1-1.5 | – | – | 9-10 | 10-13 |

Type 2: continuous chain roasting and cooling machine

A continuous chain roasting machine is widely used to process peanuts, cashews, walnuts, pistachios, almonds, broad beans, and other granular nuts. The equipment heats the materials evenly and efficiently. It can realize continuous feeding and discharge with high efficiency.

The baking temperature and time are both controllable. Equipped with a circulating air device, the machine cools the roasted material after roasting. The machine capacity ranges from 100kg/h to 1ton/h. Its heating source can be gas or electricity.

Parameter

| Machine type | Transmission power(kw) | Heating Power(kw) | Thickness of raw materials(mm) | Output(kg/h) | Dimension(mm) |

| TZ-200 | 10 | 46 | 50-60 | 200 | 6900x1500x2600 |

| TY-300 | 10 | 70 | 50-60 | 300-350 | 7500x1500x2600 |

| TZ-1000 | 15 | 230 | 50-60 | 1000 | 9000x3000x2600 |

Groundnut peeling machine

Type 1: small-output peanut peeling machine

The peanut peeler machine can remove the red skins of peanuts of different specifications. Our company has specialized in producing roasting machines made of high-quality materials.

There are two types of peeling machines. They are dry-type and wet-type peeling machines. Peeling machines can process soybeans, peanuts, almonds, and others.

Technical Parameter

| Model | Capacity(kg/h) | Power(kw) | Voltage(v) | Dimension(mm) | Weight(kg) | Peeling rate |

| TZ-1 | 200 | 0.75 | 380 | 1100x400x1100 | 130 | 96-98% |

| TZ-2 | 400 | 1.5 | 380 | 1100x600x1100 | 200 | 96-98% |

| TZ-3 | 600 | 2.61 | 380 | 1180x900x1100 | 300 | 96-98% |

Type 2: peanut peeling machine with medium and large outputs

This type of peanut peeling and split machine has the features of high output (500-1000kg/h), high peeling rate (98%), and excellence in removing peanut germs (90%). The three rollers in the peeling machine can efficiently peel the red peanut skins, and the sieves split the two halves of the peanut kernels through vibration.

Parameter

| Model | TZ-1 | TZ-2 |

| Motor power | 1.5KW | 2.2KW |

| Output | 500-600kg/h | 1000kg/h |

| Peeling rate | >98% | >98% |

| Dimension | 1900x850x1350mm | 1900x1150x1350mm |

| Voltage | 380V | 380V |

| Frequency | 50HZ | 50HZ |

Peanut Butter Grinding Machine

Type 1: single peanut butter grinder

The peanut grinding machine is widely applied in the food industry, chemical industry, pharmaceutical industry, etc. It can crush, emulsify, and comminute raw materials. Therefore, the peanut butter grinding machine is suitable for the fine grinding of fluid and semi-fluid materials.

The peanut grinder machine can be used to produce a wide range of foods and beverages, such as ice cream, fruit juice, sesame butter, jam, milk, etc.

Type 2: combined peanut grinder

In the peanut butter production line, the combined peanut grinder machine with higher capacity and fineness is often used. Our peanut milling machines have been exported to many countries around the world, such as the Philippines, India, Kenya, and South Africa.

Technical Parameter

| Model | TZ-70 | TZ-85 | TZ-130 | TZ-180A | TZ-200A |

| Power(kw) | 3 | 5.5 | 11 | 30 | 37 |

| Dimension(mm) | 650x320x650 | 900x350x900 | 1000x350x1000 | 1200x450x1200 | 1200x500x1200 |

| Weight(kg) | 70 | 170 | 270 | 470 | 500 |

| Capacity(kg) | 60-80 | 100-150 | 200-300 | 500-800 | 600-1000 |

| Voltage(v) | 220 | 380 | 380 | 380 | 380 |

| Fineness(mesh) | 120-150 | 120-150 | 120-150 | 120-150 | 120-150 |

Storing, mixing, and degassing tanks

A peanut mixing tank is a piece of equipment used for blending, heating, emulsifying, and mixing raw materials. The material is stainless steel. The mixing tank is composed of a mixing tank body, mixing tank cover, agitator, support, transmission device, shaft seal device, etc. A vacuum tank can remove the air to extend the shelf life of peanut butter.

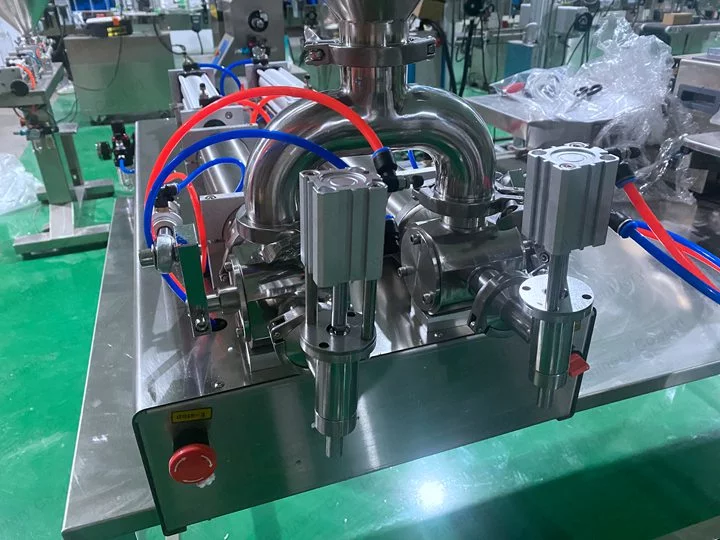

Peanut butter packaging machine

Type 1: Semi-automatic Butter Filling Machine

The semi-automatic peanut butter filling machine is for filling and packing butter. But its use has extended to many products as well. Paste filling machines are also suitable for filling paste, jellies, and jams, especially highly viscous paste. The driver of this filling machine is compressed air.

The peanut butter filler is made of 304 stainless steel. Packaging container varies from bags, bottles, cans, pouch and stand-up pouches.

Type 2: Automatic Peanut Butter Packing Machine

In a fully automatic peanut butter packing line, there is a bottle unscrambler, an automatic filling machine, a capping machine, and a labeling machine. The machine series is quite labor-saving and time-saving.

Advantages of Peanut Butter Production Line

- High productivity and various outputs available. The output capacity reaches 50kg to 2tons per hour.

- High efficiency. The Peanut Butter processing equipment is highly automatic, which can realize continuous operation and save a lot of labor.

- High-quality product. The fineness of the peanut butter is high, reaching 125-150 meshes. The product is hygienic and safe, meeting food safety standards.

- Customized service available. We offer customization services for specific needs in terms of machine material, capacity, voltage, machine size, product fineness, etc.

- Wide application. The peanut butter processing line is also suitable for processing other nuts or seeds, like almonds, walnuts, sesame, cashew nuts, etc.

Typical Cases

Peanut Butter Machine in the Philippines

peanut butter machine in Nigeria

If you need more information about our peanut butter processing line, please contact us directly.