The semi-automatic peanut butter production line is a compact and efficient processing solution with a flexible output capacity of 50–200 kg/h, designed for small to medium peanut butter manufacturers.

By integrating peanut roasting, dry peeling, fine grinding, and semi-automatic filling into one streamlined system, this line ensures consistent flavor, smooth texture, and hygienic production while keeping investment and operating costs under control.

The peanut butter processing line is mainly used by small-scale nut processing plants, which can effectively improve production efficiency.

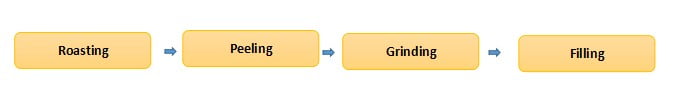

Flow chart of pure peanut butter production

After peanuts are harvested and shelled, they are ready for further processing to become peanut butter. In a small-scale peanut butter processing line, the main steps are roasting, peeling, grinding, and filling.

Benefits of a small peanut butter production line

Compared with a large-scale production line, it has the following benefits.

- Relatively low investment and quick return

- Moderate production efficiency

- Flexibility in the production process

- Wide application: suitable for various pastes, sauces, jams, etc.

Main equipment in pure peanut butter manufacturing Line

1. Peanut roasting machine

The peanut roaster machine can realize even heating with an advanced rotary drum structure and automatic temperate control system. It can be heated by gas or electricity.

2. Roasted peanut peeling machine

The roasted peanut peeling machine has a high peeling rate and low breakage rate. The peeler can also suck the red skins of peanuts away.

3. Peanut butter grinding machine

The combined peanut butter grinding machine can realize high fineness with double grinding.

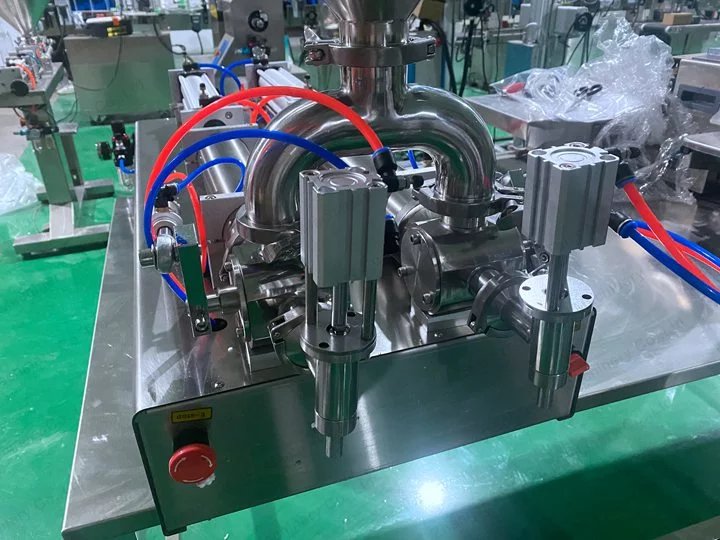

4. Semi-automatic peanut butter filling machine

The peanut butter filling machine is a semi-automatic filling equipment with an https://www.peanut-butter-machine.com/automatic-peanut-butter-production-line.htmlaccurate filling volume. Packaging containers can be bottles, cans, stand-up pouches, etc.

Highlights of peanut butter processing equipment

- This small peanut butter production line has a compact structure, reasonable design, and high performance.

- Other advantages are accurate roasting temperature, ideal grinding, controllable filling volume, stable and reliable operation, high work efficiency, and long service life.

- Peanut butter has the characteristics of high fineness, bright color, and pure and attractive taste.

Small peanut butter production line specification

| Item | Parameter |

| Peanut roaster machine | Capacity:100kg/h Motor power:1.1kw Heating power:18kw Weight:600kg Temperature 0 –300° |

| Peanut peeling machine | Motor Power:0.55kw Capacity:200-300kg/h Fan power:0.75kw Voltage:380V/220V Purity:98% Size:1100*400*1100MM |

| Combined Grinding machine | Processing fineness:2-100um Size:110*75*130cm Power:5.5*2kw |

| Semi-automatic Butter Filling Machine | Air Pressure(MPa): 0.4-0.6 Weight(Kg) : 50 Driven Type : Electric Filling Speed(bottles/Min) : 20-60 Filling Range(ml) : 300-1000 |

Applications

The semi-automatic peanut butter production line (50–200 kg/h) is suitable for a wide range of food processing scenarios, especially where flexibility, product quality, and controlled investment are required.

Typical applications include:

- Small and medium peanut butter factories

- Food startups and new peanut butter brands

- Nut butter workshops and local food processors

- Private-label peanut butter production

- Customized peanut butter (smooth or coarse texture)

- Regional distribution and specialty food markets

This production line is ideal for manufacturers looking to start peanut butter production with a scalable capacity and gradually expand as market demand increases.

FAQs

What is the actual production capacity of this line?

The standard output capacity ranges from 50 to 200 kg per hour, depending on peanut roasting conditions, grinding fineness, and operator experience.

Can the line be upgraded in the future?

Yes. The semi-automatic peanut butter production line can be upgraded with larger machines, buffer tanks, or automatic filling and labeling systems.

How many operators are required?

Typically, 2–3 workers are sufficient to operate the complete line.

Contact Us

If you plan to build a semi-automatic peanut butter production line with a capacity of 50–200 kg/h, or require technical advice on equipment selection, factory layout, and production planning, please contact us.

Our professional team will help you with:

- Equipment configuration based on your capacity target

- Process optimization for peanut butter quality

- Line layout and expansion planning

- Technical support and after-sales service

Contact us today to receive a customized solution and detailed technical guidance for your peanut butter production project.