The continuous peanut roaster is a new multi-functional automatic roasting machine. The industrial nut roaster is mainly used for the roasting of nuts, beans, seeds, and other materials, such as cashew nuts, hazelnuts, chestnuts, soybeans, and sesame seeds. It is often used in automatic nut processing lines, including the peanut butter production line.

The equipment is ideal for roasting peanuts, beans, and seeds in large quantities in the food processing industry. The chain plate baking machine has a production capacity ranging from 50 to 2000 kg/h and can be customized to meet specific requirements.

Continuous peanut roaster highlights

- High productivity. The output can reach 50-2000kg per hour.

- Multifunctional. The roasting and cooling integrated design allows the materials to automatically enter the cooling area. Thus, the material is convenient to store and further process.

- High degree of automation. The continuous peanut roaster has automatic temperature control and excellent roasting and cooling effects.

- Good roasting quality. The circulating fan can make a strong air flow for roasting, improve baking efficiency. The temperature in the continuous roaster machine is uniform.

- Diverse heating sources. The heat source can be electricity or gas.

- Fire monitoring system. The chain-link baking machine is equipped with a fire alarm system that automatically triggers an alarm upon detecting excessive temperatures or the occurrence of a fire.

Applications of the chain plate peanut roaster

This machine is widely used for roasting:

Peanuts

Almonds

Cashew nuts

Hazelnuts

Soybeans

Sunflower seeds

Pistachios

Mixed nuts

Coffee beans

It is suitable for flavored nuts, snack foods, coated peanuts, and pre-roasting before oil extraction.

Working principle of the continuous nut roaster

The continuous peanut roaster, a jet air roasting type, makes hot air flow up and down to the materials on the metal chain plate. Due to the high jet speed, the heat transfer coefficient is high, and so is the roasting speed.

It has strong penetration and diffusion within the materials. The material thickness can be up to 50-60mm. The heat source can be electricity or gas.

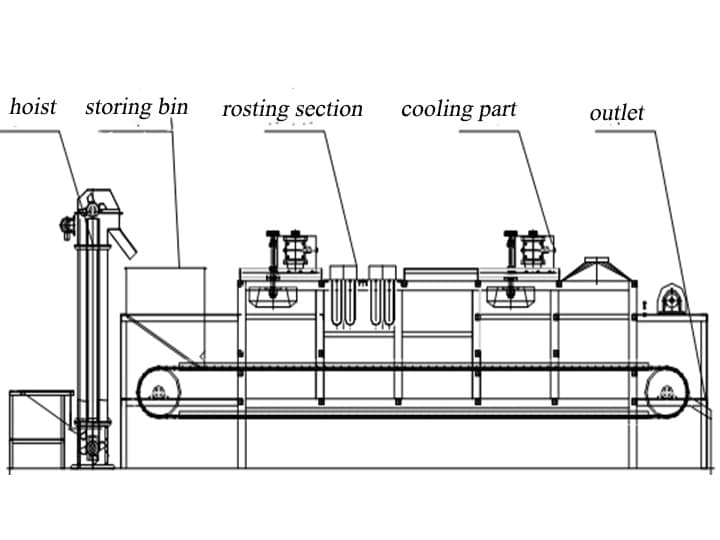

Continuous nut roasting machine structure

The continuous roaster mainly includes a conveyor system, roasting part, and cooling part. The segmented heating of the roaster can achieve the results of independent temperature control and independent electric box control. The transmission speed is changeable.

Parameters of the chain plate nut roaster

| Machine type | Transmission power(kw) | Heating Power(kw) | Thickness of raw materials(mm) | Output(kg/h) | Dimension(mm) |

| TZ-200 | 10 | 46 | 50-60 | 50-200 | 6900x1500x2600 |

| TY-300 | 10 | 70 | 50-60 | 300-500 | 7500x1500x2600 |

| TZ-1000 | 15 | 230 | 50-60 | 500-2000 | 9000x3000x2600 |

If you need more information about the continuous roaster, please contact us directly.

Features of the continuous peanut roasting machine

- High output: suitable for large-scale roasting factories

- Uniform roasting: hot air penetrates evenly for consistent color and flavor

- Energy saving: double-layer insulation and efficient heat utilization

- Adjustable temperature and time: suitable for different nuts and roasting levels

- Hygienic design: crafted from food-grade stainless steel

- Continuous production: ideal for integration into nut processing lines

FAQs about the nut roaster

Can the machine roast other nuts besides peanuts?

Yes, it works for almonds, cashews, beans, seeds, and other granular foods.

Can the roaster be connected to a full nut processing line?

Yes, it can be integrated with cooling, seasoning, and packaging machines.

What is the production capacity of the chain plate baking machine?

Production capacity ranges from 50 to 2000 kg/h and can be customized to meet specific requirements.

Contact us!

Looking for a high-performance peanut roasting machine? We provide customized continuous peanut roasters for different heating types, capacities, and nut processing requirements.