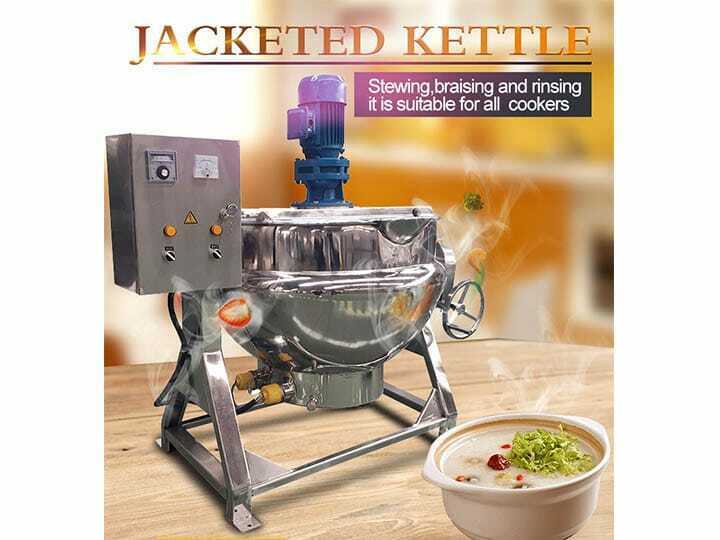

A steam-jacketed kettle is also known as a steam cooking pot. The double-layer structure, like a double boiler, can realize even heating and cooking. The large and deep pot can cook large amounts of food with steam heat between the inner and outer steel layers. The jacketed kettle has wide applications, often used to make soup, sauce, porridge, broth in canteens, hotels, and restaurants, or produce syrup, candy, dairy products, liquor, cakes, beverages in food processing factories. It is also an important machine used in peanut brittle candy production line. The steam-jacketed kettle has fixed type, tilting type, stirring type, and others with multiple functions.

Highlights of steam-jacketed kettle

- High thermal efficiency, large heating area and short boiling time

With advanced structure design, the jacketed kettle heats quickly than traditional pan or pot.

- Uniform heating and controllable temperature

The sugar melting pot has a uniform heating surface. It is easy to control the temperature, which can avoid burning food.

- Safe and convenient

The inner pot body of the syrup cooking pot is made of acid and heat-resistant stainless steel, equipped with pressure gauge and safety valve. It has the features of easy installation, convenient operation, safety and reliability.

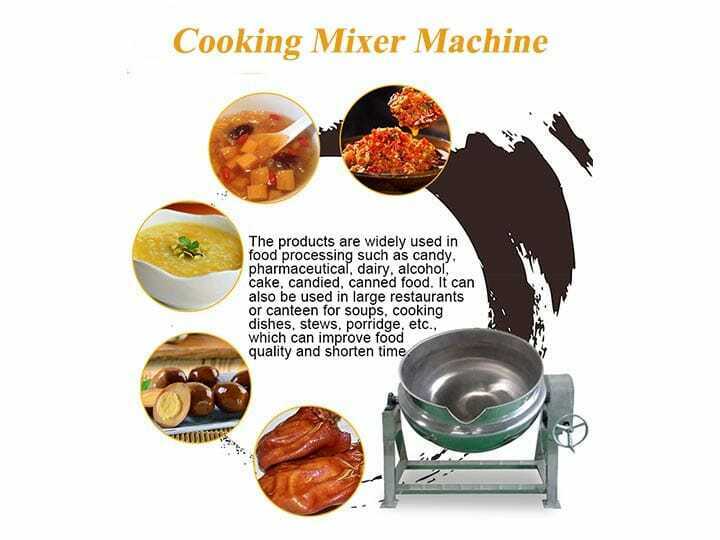

- Wide application

The cooking mixer machine is applicable to cook sugar, honey, soup, sauce, stew, pasta, dessert, etc. It is widely used in food and beverage industries.

- Multiple heating methods

Natural gas, liquid gas, biogas, electricity, steam are all the heating sources of the sugar melting pot.

Jacketed kettle types and structures

The steam-jacketed kettle has different types based on the following classifications.

- In light of structural form, there are tilting and stationary jacketed kettles. The stationary type mainly comprises pot body and supporting feet. Tilting type mainly contains pot body and tilting frame, such as turbine, rod, handwheel and bearing seat.

- In terms of the process, there are jacketed pot with mixer or without mixer. The main parts of the jacketed kettle with mixer are a pot body and a stirring device.

- According to the sealing mode, there are uncovered type and covered type. The cooking mixer machine with a cover can keep the pot from pollution when it is not in use.

Parameter of 200L Electric Model

| Voltage | 440V, 50HZ, 3phase |

| Power | 18KW |

| Diameter | 800mm |

| Material | 304stainless steel |

Steam-jacketed kettle check and installation

- Check whether the products and parts of tilting kettle are damaged during transportation.

- Place the equipment on a flat and hard ground.

- The power supply shall meet the requirements of the equipment, and the equipment shell must be well grounded to avoid leakage accidents.

- Make sure that the oil inlet pipe is unblocked without blockage.

Operation instruction and cleaning

- There are oil filler and oil overflow port at the back of the steam-jacketed kettle. After refueling, close the oil overflow valve and rotate the oil filler to the ground.

- Connect the power line and open the circuit breaker in the distribution box.

- Set the temperature on the digital display temperature controller. The temperature setting range is 0-230 degrees. It will automatically turn off when it reaches the set temperature.

- In order to ensure the cleanness of heat transfer oil, check it every 3-6 months. When the boiler bottom valve is opened to drain oil, the temperature should be reduced to less than 50 degrees.

- Clean the pot once a day and rinse it with water directly.

Jacketed kettle in working mode

Related articles