An automatic peanut brittle machine is used to produce candied roasted peanut snacks. The peanut candy production line mainly consists of 6 machines: a peanut roaster, a peanut peeler, a sugar melting machine, a peanut brittle forming and cutting machine, a peanut brittle mixing machine, and a peanut candy packing machine.

The production capacity of the peanut candy production line ranges from 50 to 2000 kg per hour.

Peanut candy production line advantages

- Highly automatic and labor-saving

- Uniform and adjustable product sizes and shapes

- Stable and continuous operation and high yield

- Easy to operate and maintain

- Wide application. Suitable for various candied snacks with nuts or seeds

- Customized service available.

Video of the peanut candy cutting machine

What machines are included in the peanut candy bar production line?

The peanut brittle processing line mainly includes the peanut roaster, a peanut peeler, a sugar cooking machine, a peanut brittle forming and cutting machine, a peanut candy mixing machine, and a peanut candy wrapping machine, as well as auxiliary equipment.

1. Peanut roaster machine

The peanut roaster machine is designed to roast peanuts and other nuts or beans, like almonds, cashew nuts, walnuts, chestnuts, sesame seeds, cocoa beans, etc. The advanced drum structure can enable the machine to heat materials evenly and efficiently, with an output of up to 1000kg/h.

2. Peanut peeling machine

The roasted peanut peeling machine is used to remove the red skins of peanut kernels. It has a high peeling rate and a low breakage rate. The output can be from 200 to 1000kg per hour.

3. Steam-jacketed kettle

To make peanut candy, syrup is an essential ingredient. A steam-jacketed kettle, also known as a syrup cooking pot, is used to melt sugar for making syrup. It has a double-layer structure with inner and outer spherical pot bodies.

The sugar melting pot has the characteristics of a large heating area, uniform heating, high thermal efficiency, various heating methods, easy operation, and a tilting function.

The general structure contains a mixing rod, cover, pot body, motor, thermometer, hand wheel, control cabinet, etc. The thickness of the pot is 3mm, and the popular volume ranges from 100 to 600L. The finished product can be discharged easily.

The sugar melting pot is widely used in the processing of all kinds of food, and can also meet the needs of large restaurants or canteens for cooking sauce, soup, stew, porridge, and so on.

4. Peanut brittle mixing machine

A mixing machine is used to mix the syrup with other materials, especially nuts and seeds, like peanuts, cashew nuts, almonds, walnuts, sesame seeds, sunflower seeds, etc.

The mixer machine has the features of heat preservation effect, temperature control system, corrosion resistance, high-temperature resistance, non-adhesion, etc. It is also convenient to discharge the products.

Technical data of the mixing machine

| Model | TZ-100 | TZ-150 | TZ-200 |

| Voltage | 380V/50hz | 380V/50hz | 380V/50hz |

| Power | 1.1kw | 1.1kw | 2.5kw |

| Size | 700*800*1200mm | 700*500*1400mm | 960*600*1200mm |

| Capacity | 10kg/batch | 15kg/batch | 50kg/batch |

5. Ascension conveyor

The lifting conveyor is to lift and send the material processed by the mixing machine to the automatic cutting machine. The surface is stainless steel, and the conveyor belt material is PVC. The general size is 2500*820*1080mm.

6. Peanut brittle forming, cutting, and cooling machine

The peanut brittle machine integrates the functions of mixing, forming, cooling, and cutting. It applies to a wide variety of snack foods, like peanut candy, puffed rice candy, cereal bar, sesame candy, granola bar, energy bar, protein bar, chikki, and caramel treats, etc.

The peanut brittle forming and cutting machine is an important part of the peanut candy production line. It can form the peanut candy into a rectangle, square, round, or other shapes.

Highlights of the peanut brittle machine

- Multiple and integrated functions.

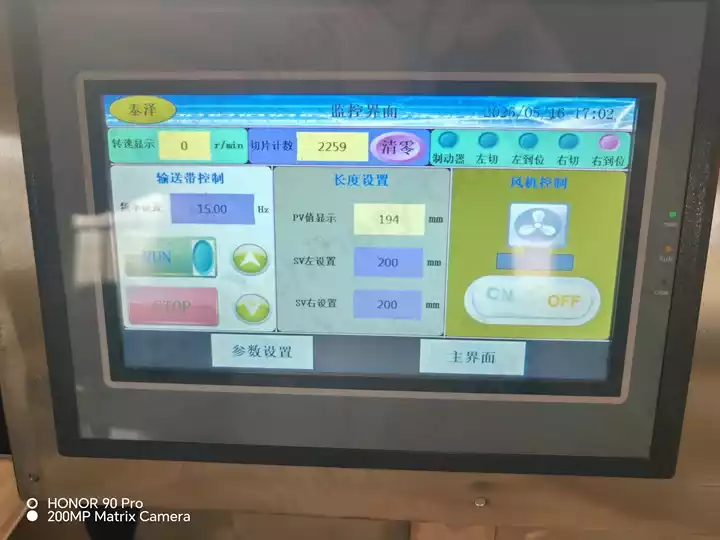

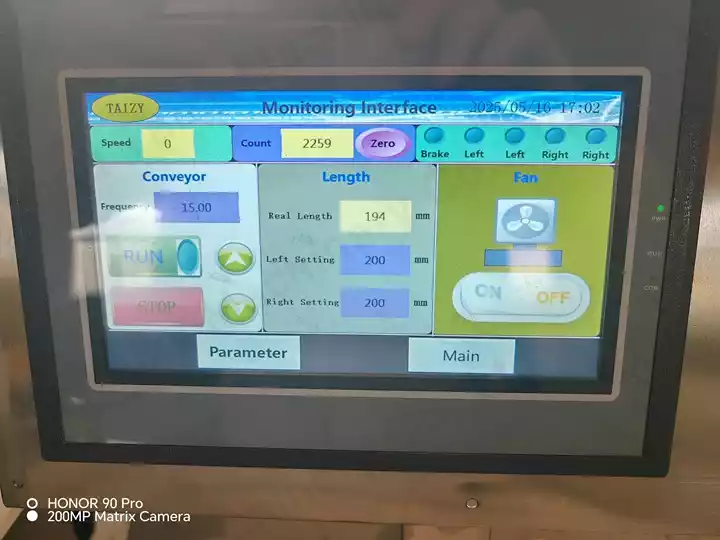

The peanut brittle forming and cutting machine firstly stirs the raw materials, and its pressing roller presses sticky raw materials into a flat shape. Then, the 3 fans immediately cool the peanut candy for a better cutting effect in the following procedure.

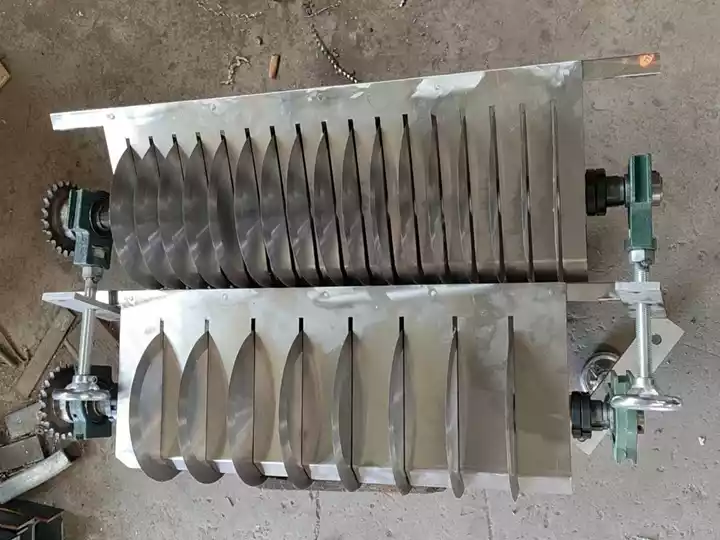

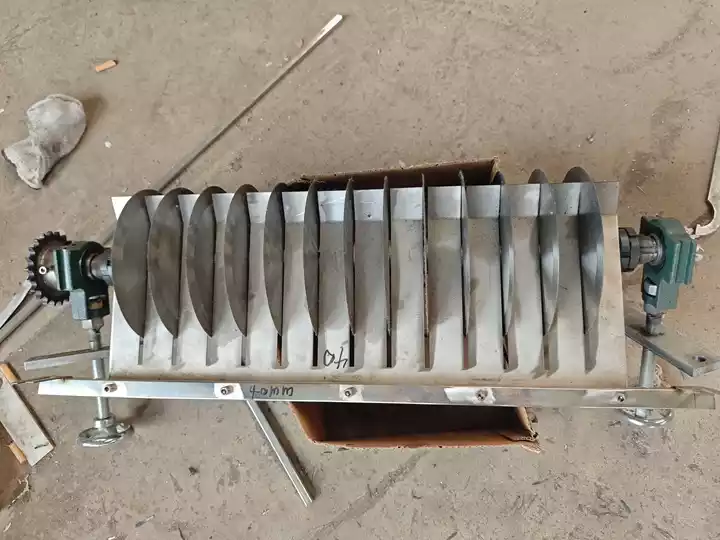

The peanut brittle machine has a cross cutter and several vertical cutters to cut the whole material into expected sizes.

- Adjustable product sizes

The conveyor belt’s width is 560mm. A cross-cutter and a set of vertical blades cut the materials on the conveyor into different lengths and widths. The speed of the conveyor is changeable to cut the materials into different lengths.

The width of the material depends on the number of vertical blades, which can be customized based on special needs. The thickness of the raw material is adjustable by using handwheels on both sides to change the height of the rollers.

Besides, we have another type of peanut brittle forming machine, called a rotary table forming machine. It has various molds that can form the materials into round, cylindrical, spherical, or other shapes.

- Hygienic and durable

The conveyor belt material is PVC, and the machine is made of stainless steel. The peanut brittle machine is quite hygienic, meeting food safety standards.

Parameter

| Model | TZ-68 | Cooling conveyor |

| Power | 2.5kw | 0.37kw |

| Motor | 380V, 50hz | 380V/220V |

| Size | 6800*1000*1200mm | 5000*1000*800mm |

| Belt width | 560mm | |

| Weight | 1000kg | |

| Capacity | 300-400kg/h |

7. Peanut candy packing machine

The final step in the peanut candy production line is packaging the finished products. Our pillow-type packing machine is suitable for packing a wide range of foods and is widely used in food processing lines. The packing speed is 50-300pcs/min.

Application scope of the peanut candy production line

This automatic peanut candy production line is widely used for producing:

- Traditional peanut brittle

- Sesame peanut candy

- Mixed nut brittle

- Caramel peanut candy

- Honey-coated peanut snacks

- Custom nut confectionery products

It supports diverse product shapes, textures, and packaging formats, suitable for domestic retail markets and export-oriented candy processing plants.

Optional customization

- Sesame candy processing configuration

- Multi-nut candy mixing system

- Automatic cutting & sizing unit

- Nitrogen-flushed packaging system

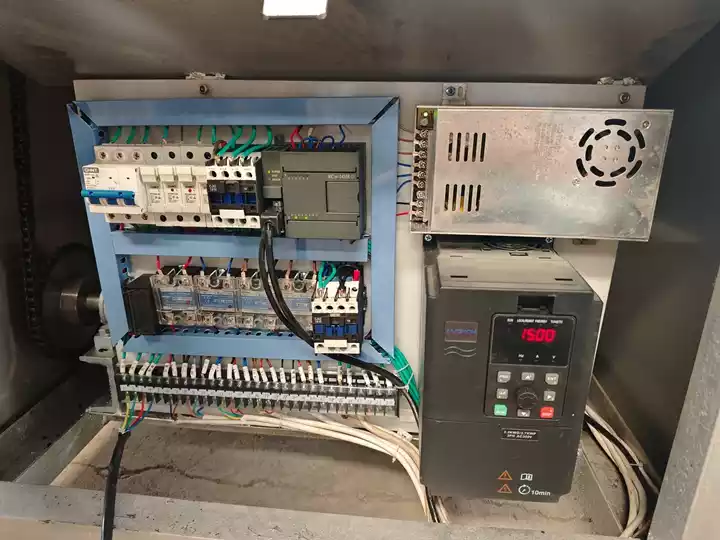

- Full PLC intelligent control

Related articles

Export cases

FAQs

What products can this production line make?

Peanut brittle, sesame brittle, nut bars, cereal bars, and other sugar-coated snack bars.

What is the production capacity?

50–2000 kg/h, depending on line size and cooking capacity.

What is the standard size of the final peanut brittle?

Length, width, and thickness are adjustable. Common sizes: 10–20 mm thick and customizable lengths.

Is the shape uniform after cutting?

Yes. The automatic cutting machine ensures precise, clean, and consistent bar sizes.

Can the line process other nuts besides peanuts?

Yes. Almonds, cashews, sunflower seeds, sesame seeds, mixed nuts, etc.

Do you offer installation and after-sales service?

Yes. We provide layout design, operation training, online installation guidance, and spare parts support.

Contact us!

If you are planning to build a peanut candy production line with a capacity of 50–2000 kg/h, our engineering team is ready to provide:

- Customized equipment configuration

- Factory layout planning

- Technical guidance and training

- Turnkey production line solutions

Contact us today to receive a professional proposal and quotation for your peanut candy manufacturing project.