The automatic snacks frying machine is a piece of equipment widely applied in the food processing industry. The automatic snack fryer machine is used for frying snack food, including nuts, meats, pasta, vegetables, like peanuts, coated peanuts, cashew nuts, chicken, pork skins, french fries, banana chips, potato chips, falafel, and so on. The snack frying machine is an important part of the fried peanut production line. We have specialized in manufacturing automatic snacks frying machines for more than ten years, delivering the machinery to many countries, like the Philippines, Thailand, etc. Three types of deep-frying machines are available: basket deep frying machine, automatic stir frying machine, and continuous deep fryer.

Basket deep frying machine for snacks

This type of automatic snacks frying machine is suitable for small and medium-sized fried food processing plants.

- This snack frying machine can avoid large amounts of oil volatilization caused by overheating of the traditional fryers. High and low temperature oil technology prevents the residue under the oil layer from being burnt, so as to avoid a large amount of oil waste.

- The snack food frying machine has advanced intelligent digital display temperature control device. After you select the temperature according to the fried food, it will automatically control the on-off of the circuit to ensure constant temperature. This not only greatly reduces the energy consumption, but also makes the operation easier and faster.

- The heanting source can be electricity or gas, and it is easy to operate and clean. There are two handles used for lifting the baskets to discharge the food.

- Multiple options of outputs. The output varies with the number of baskets and basket size. Each basket can work independently.

Technical parameter (electric type)

| Type | Model | Number of basket | Dimension (mm) | Weight (kg) | Power (kw) | Capacity (kg/h) |

| Electricity-heating | TZ-500 | 1 | 700*700*950 | 70 | 12 | 50 |

| Electricity-heating | TZ-1000 | 2 | 1200*700*950 | 100 | 24 | 100 |

| Electricity-heating | TZ-1500 | 3 | 1700*700*950 | 160 | 36 | 150 |

| Electricity-heating | TZ-2000 | 4 | 2200*700*950 | 180 | 42 | 200 |

| Electricity-heating | TZ-3000 | 6 | 3300*1100*1300 | 400 | 72 | 300 |

Technical parameter (gas type)

| Type | Model | Dimension (mm) | Weight (kg) | Capacity (kg/h) |

| Gas-heating | TZ-1000 | 1500*800*1000 | 320 | 100 |

| Gas-heating | TZ-1500 | 1900*800*1000 | 400 | 150 |

| Gas-heating | TZ-2000 | 2200*800*1000 | 700 | 200 |

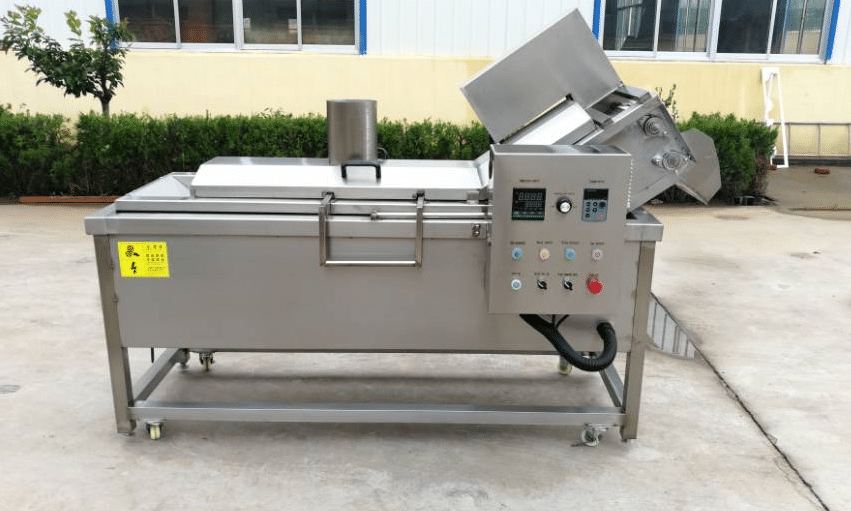

Automatic stir snack fryer machine

This type of automatic snacks frying machine is also called a semi-automatic batch fryer, or auto stir fryer machine, suitable for medium-sized food processing plants. It’s able to fry nuts, root vegetables, flour-made food, meat, and other material. This fryer has an automatic stirring and discharging function and can be equipped with an automatic feeding device. It supports electricity or gas heating. The deep fryer is composed of a pot body, a control panel, a specifically designed insulation system, heating tubes, and an electric motor.

Technical Parameter

| Model | Power | Capacity | Size | Weight |

| TZ-Y1000 | 36kw | 100kg/h | 1400*1200*1600mm | 300kg |

| TZ-Y1200 | 48kw | 150kg/h | 1600*1300*1650mm | 400kg |

| TZ-Y1500 | 60kw | 200kg/h | 1900*1600*1700mm | 580kg |

Advantages of auto stir fryer machine

- Multiple-use The electric deep fryer can fry peanuts, potatoes for making French fries, potato chips as well as many other raw materials.

- Labor-saving and cost-saving The fryer can feed and discharge automatically.

- More choices for heating methods Electricity, or gas.

- Automatic temperature control Energy-saving.

- Food safety and operation safety The machine material is food-grade 304 stainless steel. And the deep fryer protects workers from scalding.

Video of auto stir frying machine

Continuous automatic snacks frying machine

This snack frying machine is also called a mesh belt fryer or continuous frying machine. The automatic snacks frying machine has a high output (500-2000 kg/h) and is often used in the automatic fried food production line, such as fried peanut production line, potato chips production line, or French fries production line in medium or large food processing plants.

- This continuous deep fryer is a double mesh belt that prevents the product from floating and makes the food more even in the frying process.

- The deep fryer machine has high automation with multiple functions. The snack frying machine includes an automatic lifting system, automatic conveyor belt, automatic heating system, oil circulation system, smoke exhaust system, residue removal system, etc.

- It also has a variable speed control system, which is suitable for frying various foods (such as peanuts, tofu, chicken, fish, meatloaf, meatballs, potatoes, etc.).

- The automatic snack fryer machine is made of stainless steel, and it can avoid excessive acidification of fried foods.

Automatic conveyor frying machine advantages

- Multi-functional and multiple heating methods. The continuous deep fryer can process many kinds of foods. The heating sources can be gas or electricity.

- High productivity. The maximum output can be 2000 kg/h.

- Automatic control system. Continuous fryer is equipped with an automatic control system. The working temperature can be set within the range of 0-300 degrees.

- Hygienic and easy to clean. First, mesh belt conveyor fryer machine is made of stainless steel, which is anti-rust and anti-corrosion. Second, automatic belt frying machine has automatic scraping system to remove the food residue. Third, the cover can be lifted for cleaning the inside.

- Automatic filtration system: oil-saving and clean.

Mesh Belt Fryer Technical Parameter

| Model | Power | Capacity | Size | Weight |

| TZ-LX3500 | 80kw | 500kg/h | 3500*1200*2400mm | 1000kg |

| TZ -LX4000 | 100kw | 600kg/h | 4000*1200*2400mm | 1200kg |

| TZ -LX5000 | 120kw | 800kg/h | 5000*1200*2400mm | 1500kg |

| TZ -LX6000 | 180kw | 1000kg/h | 6000*1200*2400mm | 1800kg |

| TZ -LX8000 | 200kw | 1500kg/h | 8000*1200*2600mm | 2000kg |