The seasoning machine for snacks is designed to add flavor to many kinds of foods in the food processing industry, including fried peanuts, popcorn, french fries, potato chips, banana chips, fruit chips, puffed snacks, etc. This seasoning machine snack is also a popular machine in many production lines, like the peanut coating production line, potato chips production line, french fries processing line, etc.

Working video of octagonal seasoning machine

Seasoning machine for snacks working principle

The rotary octagonal blender machine has outstanding features of high automation, uniform mixing, and no breakage. After the seasoning machine for snacks starts, the materials in the drum move evenly and get mixed with the seasoning.

During the working process, the food and seasoning powder is always kept in the drum. The design of an inward barrel mouth can well avoid material spilling, increase output and achieve the purpose of uniform mixing. When the flavoring machine discharges the material, the redundant powder and well-flavored products are automatically separated.

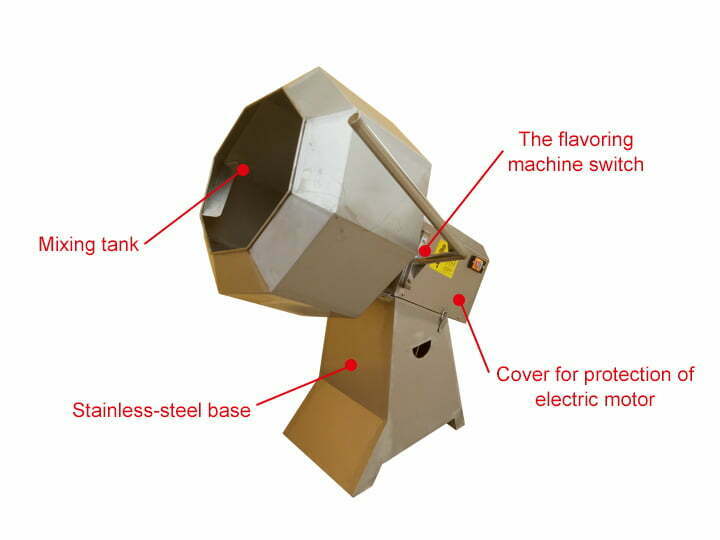

Structure of seasoning machine snacks

The rotary food flavoring machine consists of a mixing tank, the flavoring machine switch, a stainless-steel base, a cover for the protection of the electric motor, and a switchboard. The nuts flavoring machine can be equipped with an automatic dusting device and a spraying device.

Features of seasoning machine for snacks

- Food-grade stainless steel: The parts in contact with the food are made of 304 stainless steel, which meets national health and safety standards.

- Uniform mixing and no stickiness. The unique shape design can ensure a uniform mixture.

- Various models and types: There are two types of fried flavoring machines and various capacities. They are the roller type and the octagonal type. We also support customized services.

- Multiple uses: The fried food flavoring machine can flavor fried peanuts, French fries, plantain chips, and potato chips in the food processing industry.

- High productivity: the general output reaches up to 1500kg per hour. Also, we can customize the machine to meet customers’ specific needs.

- Automatic system: Automatic mixing, dusting, spraying, and discharge functions.

Operation of seasoning machine for snacks

- Make a detailed inspection before starting the machine, including whether the fastening parts are loose, whether the power line is damaged, whether there are impurities in the barrel, and whether the voltage meets the requirements.

- Start the machine after placing it stably. After the machine runs safely for one minute, stop the machine and put in the required raw materials and seasonings.

- After the machine works for a period of time, observe that the materials required for seasoning are mixed evenly. After meeting the requirements, stop the machine.

- Hold the control lever, pull the barrel forward, and pour out the material.

Automatic chips flavoring machine technical data

| Model | Dimension(mm) | Weight (kg) | Power (kg) | Capacity |

| CY800 | 1000*800*1300 | 130 | 1.1 | 300kg/h |

| CY1000 | 1100*1000*1300 | 150 | 1.5 | 500kg/h |

| CY2400 | 2400*1000*1500 | 300 | 0.75 | 1000kg/h |

| CY3000 | 3000*1000*1600 | 380 | 1.1 | 1500kg/h |

Stock Display of Multiple-Use Flavoring and Mixing Machine

Related article

popcorn flavoring machine

peanuts flavoring machine

Another model of flavoring machine

Our company offers another model of seasoning machine for snacks, the fried food flavoring machine. It is also called a continuous seasoning machine with high output.

If you would like to know more about the seasoning machine for snacks, please do not hesitate to contact us.