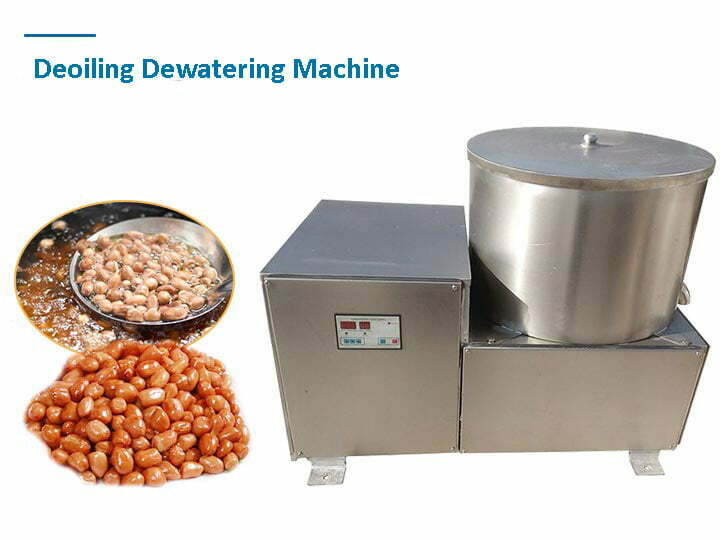

Fried food oil extractor is professionally designed to remove redundant oil from large quantities of fried foods, like fried peanuts, French fries, fried chicken, fried fish, potato chips, etc. The oil separator for fried food is often used in various food production lines, including Fried Peanut Production Line. As the Oil Removing Machine from food can extract water from food, it is also suitable for dewatering in fruit and vegetable processing lines. The oil dryer machine can be applied to small and medium-sized restaurants, food processing plants, and so on.

frying French fries

washing fruits and vegetables

Why is the fried food oil extractor needed?

The snack food deoiling machine is often paired with a frying machine in fried food processing lines.

On the one hand, Fried food contains too high oil after being fried. Too much oil is bad for the taste and flavor of final fried food. Therefore, a deoiling machine is in need.

On the other hand, as water is sometimes included in the food, the dewatering machine is applied to get rid of excessive water for longer shelf life.

Hence, the fried food deoiling machine plays an important role in the fried food production lines. The fried food oil extractor is to extract extra oil produced in the step of frying.

Deoiling dewatering machine for fried snack food introduction

The fried food oil extractor is made of 304 stainless steel, which meets food safety standards. With high efficiency and controllable time, it is popular in the food processing industry. The deoiling machine is suitable for the fried snack food production industry or the fruit and vegetable processing industry. The oil removal machine is applicable to individuals or large plants that require dehydration or oil removal.

Oil Removal Machine Working Principle

It is easy to figure out how the fried food oil extractor operates. The snack food deoiling machine conducts centrifugal movement and the working time is based on the time set specifically. The electric motor drives the inner tank to rotate at extremely high speed. The moisture or extra oil in the wet or fried material splashes under high-speed rotation so as to realize achieve dehydration. When the set time is up, the oil remover machine stops working.

Video of oil dryer machine in working mode

Machine details of oil removing machine from food

(1) The fried food oil extractor is made of shockproof rubber. Due to the unbalanced load in the drum, the vibration of the foot can be avoided when running.

(2) The shell is made of stainless steel.

(3) The outlet pipe is located on the side of the barrel.

(4) The spindle is made of stainless steel equipped with two bearings.

(5) The deoiling machine adopts the timing controller to adjust the working time. Working hours can be set freely according to the raw material dehydration time.

Technical Parameter

| Model | Dimension(mm) | Weight(kg) | Power(KW) | Capacity(kg) |

| TZ-400 | 1000*500*700 | 360 | 1.1 | 300 |

| TZ-500 | 1100*600*750 | 380 | 1.5 | 400 |

| TZ-600 | 1200*700*750 | 420 | 2.2 | 500 |

| TZ-800 | 1400*900*800 | 480 | 3 | 700 |

Other types of deoiling machines applied in production lines

This de-oil machine has large outputs and can automatically discharge the materials, which is efficient and labor-saving. The oil dryer machine is often applied in fried food production lines.

This type of deoiling machine removes oil or water through vibrating screens. It can realize continuous operation. The hydro extractor machine or oil removing machine is also commonly used in food processing lines.