Have you ever wondered how raw almonds are processed from hard shells into clean, market-ready kernels? A complete almond shelling line is designed to automate this entire process — improving efficiency, reducing labor, and ensuring maximum yield.

Whether you run a nut processing factory or plan to enter the almond industry, understanding each core machine in the almond shelling line is essential for making the right investment decision.

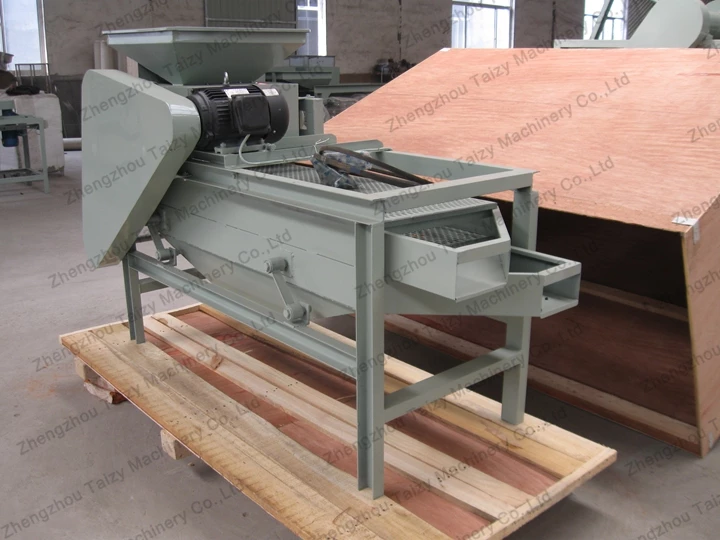

Almond Grading Machine

Before shelling, almonds must be graded according to their size.

The almond grading machine uses vibrating screens or roller systems to separate almonds into multiple grades.

This step is crucial because almonds of different sizes require different shelling pressures — uniform grading prevents over-crushing small nuts and under-shelling large ones.

Key benefits:

- Ensures accurate shelling with minimal breakage

- Improves shelling efficiency

- Adjustable screen size to fit various almond types

Almond Shelling Machine

The heart of the almond shelling line is the almond shelling machine. It uses a high-speed rotating roller or blade mechanism to crack the hard almond shells without damaging the kernels inside.

Depending on the model, the shelling rate can reach 98%, with kernel damage under 3% — a key factor in maintaining product quality and profit.

Features of the almond shelling machine:

- Adjustable gap for different almond sizes

- High shelling accuracy with low kernel loss

- Stainless steel construction for hygiene and durability

- Continuous, automatic feeding for large-scale production

Shell and Kernel Separator

After shelling, the mixture of shells and kernels is separated using an almond shell-kernel separator.

This equipment applies airflow and vibration technology to separate light shells from heavier almond kernels efficiently.

The result? Clean, uniform kernels ready for roasting, blanching, or packaging.

Advantages:

- 99% shell-kernel separation accuracy

- Simple structure and easy maintenance

- Compatible with different nut materials (such as apricot, hazelnut, or pistachio)

How the Almond Shelling Line Works Together

The complete almond shelling line integrates the three machines in a continuous, automated process:

- Feeding and grading

- Shelling (cracking)

- Shell and kernel separation

- Collection and packaging

This seamless flow reduces manual handling, increases productivity, and ensures consistent product quality.

Why Invest in Our Almond Shelling Line?

For almond processors, upgrading from manual cracking to an automated almond shelling machine system brings multiple benefits:

- Reduce labor costs by up to 70%

- Maintain uniform kernel quality for export

- Boost processing speed and output

- Ensure food safety and compliance

Whether for domestic processing or export-grade production, the almond shelling line helps maximize profitability while simplifying operations.

Learn More Information

If you are interested in our almond shelling production line, please feel free to contact us for more detailed images and videos of the production line. We welcome your inquiries.