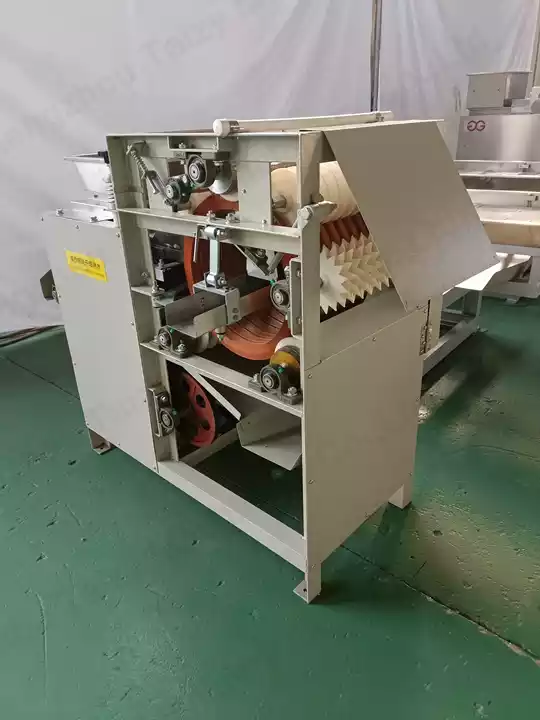

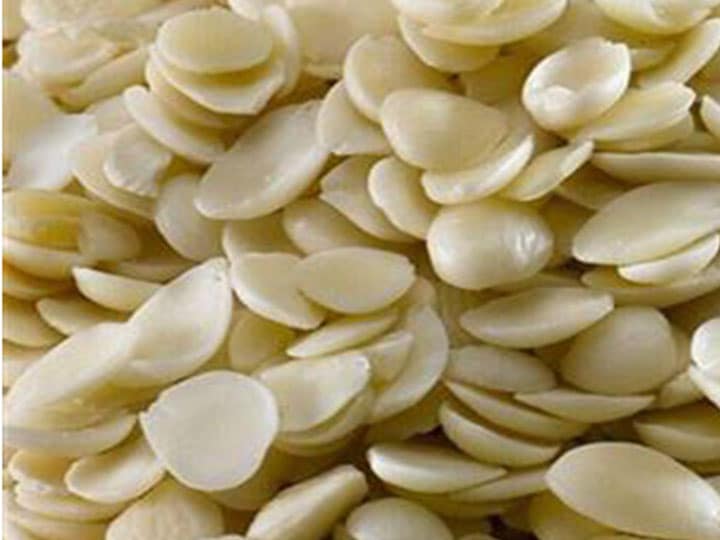

The almond peeling machine is a professional wet type almond skin removal solution designed to efficiently remove brown skins from blanched almonds while maintaining kernel integrity and appearance. By combining hot water blanching and mechanical peeling, this machine achieves a high peeling rate with minimal damage, making it ideal for food-grade almond processing.

This almond peeling machine for food processing is widely used in almond kernel factories, confectionery plants, bakery ingredient production, and almond-based food processing lines. It is also called a wet peanut peeling machine. The almond skin peeler machine has the advantages of easy operation, large output, high peeling rate (over 95%), and high quality of peeled almonds.

Nutrients of Almonds

The protein content of almonds is higher than that of general cereal crops, and the amino acid types of almonds are complementary to those of cereal crops. Almond is an excellent source of essential polyunsaturated fatty acids – linoleic acid, magnesium, and phosphorus. It is also a good source of VE, calcium, iron, zinc, copper, and B vitamins.

Applications of the Almond Peeling Machine

The wet almond peeling machine is suitable for a wide range of almond processing applications, including:

- Blanched almond kernel production

- Almond slicing and dicing preparation

- Almond flour and almond paste processing

- Chocolate, bakery, and confectionery ingredients

- Export-grade peeled almond processing

It is especially recommended where a clean surface, bright color, and intact kernels are required.

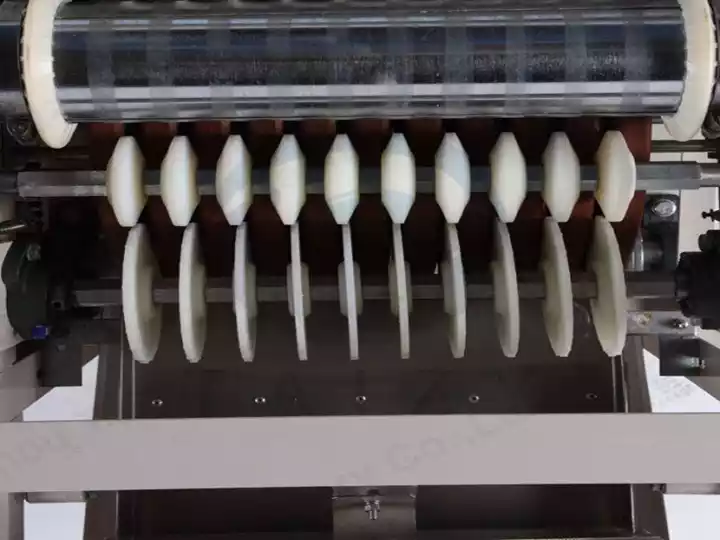

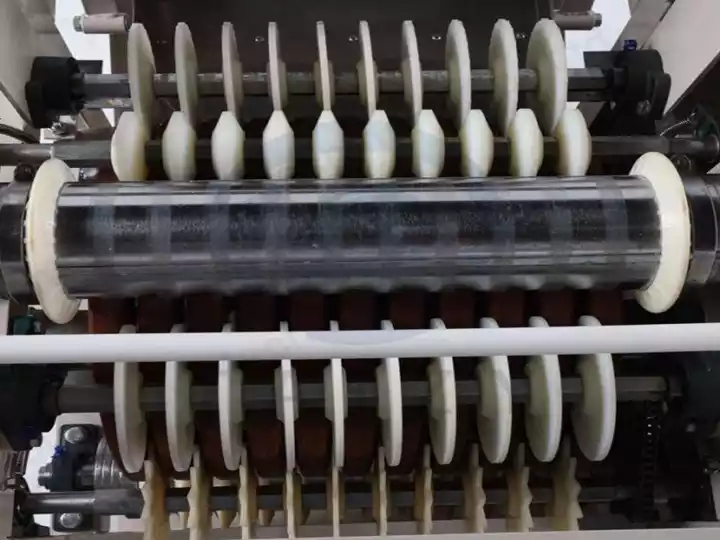

Wet Almond Peeling Machine Working Principle

The almond peeling machine operates through a hot water blanching + friction peeling process:

- Raw almonds are first soaked or blanched in hot water

- Heat loosens the almond skins from the kernels

- Almonds enter the peeling chamber, where soft friction removes skins

- Skins are discharged separately, while clean kernels are collected

This process ensures uniform peeling, high efficiency, and low kernel breakage, suitable for continuous operation.

Key Advantages of the Wet Almond Peeling Machine

High Peeling Efficiency

- Peeling rate up to 98%

- Clean and smooth almond kernel surface

Gentle Wet Peeling Process

- Reduces mechanical stress on kernels

- Maintains natural almond shape and texture

Food-Grade Construction

- Stainless steel structure

- Complies with food hygiene and safety standards

Stable and Continuous Operation

- Designed for industrial use

- Suitable for long working hours

Easy Integration

Can be connected with almond shelling machines, slicing machines, and drying equipment

Soaked Almond Peeling Line

The almond peeling production process is soaking, peeling, and selecting. Our almond peeling processing line contains an almond skin removal machine, and other supportive equipment, including a vibrating feeder, hoist, soaking machine, dividing belt, wet almond peeling machine, and pick belt. This almond peeling line is highly automatic and realizes continuous operation in the almond processing industry.

| طلب | غرض | الحجم (مم) | الطاقة (كيلوواط) | كمية | |

| 1 | تهتز المغذية |  | 1000*1000*1000 | 0.75 | 1 |

| 2 | رفع |  | 700*500*2300 | 0.75 | 1 |

| 3 | آلة النقع |  | 2900*1600*2400 | 76.5 | 1 |

| 4 | حزام التقسيم |  | 3000*500*2000 | 0.55 | 1 |

| 5 | ماكينة تقشير اللوز |  | 1150*850*1100 | 0.75 | 2 |

| 6 | حزام الاختيار |  | 6000*800*1000 | 0.75 | 1 |

لمزيد من التفاصيل حول مقشرة اللوز الصناعية أو خط إنتاج تقشير اللوز، نرحب بإعلامنا بمتطلباتك المحددة.

Frequently Asked Questions

What is the typical peeling rate?

The peeling rate reaches 96–98%, depending on almond variety and blanching conditions.

Will the machine damage almond kernels?

No. The wet peeling process is gentle and designed to maintain high kernel integrity.

Can this almond peeling machine be integrated into a full almond processing line?

Yes. It integrates easily with shelling, slicing, drying, and packaging equipment.

Contact Us!

If you are looking for a high-performance almond peeling machine or need assistance in building a comprehensive almond processing solution, please contact us.

Our team can assist you with:

- Equipment selection and capacity planning

- Almond processing line layout

- Technical support and customization

Contact us today to receive professional advice and a tailored solution for your almond processing project.