Арахисовое масло, с его насыщенным вкусом и богатым содержанием питательных веществ, стало любимцем на столах по всему миру. Для производителей пищи ключ к завоеванию рынка — это стабильное и эффективное производство арахисового масла с шелковистой гладкой текстурой и первоклассным качеством. Ответ кроется в хорошо спроектированной, высокоавтоматизированной линии по производству арахисового масла.

Итак, какое оборудование нужно для производства высококачественного арахисового масла?

Арахисовая жаровня

Это первый и наиболее важный этап, определяющий конечный вкус арахисового масла. Нежареный арахис не может дать насыщенный аромат.

Насыщенный и стабильный ли вкус?

Профессиональные жаровни используют циркуляцию горячего воздуха или нагрев барабаном, чтобы обеспечить равномерную обжарку каждого арахиса. С точным контролем температуры и времени вы можете без труда добиться разных степеней обжарки — от лёгкой до сильной — чтобы запечатать уникальный, незабываемый аромат вашего продукта.

Равномерная обжарка гарантирует, что каждая баночка арахисового масла будет иметь одинаковый профиль вкуса.

Ремень охлаждения

Только что обжаренный арахис чрезвычайно горячий. Если его сложить вместе, он продолжит готовиться, что приведёт к пережариванию. Быстрое охлаждение — ключ к сохранению оптимального вкуса.

Как предотвратить ухудшение качества и повысить эффективность производства?

Охлаждающий конвейер быстро рассеивает поверхностное тепло от арахиса с помощью мощных вентиляторов, доводя его до комнатной температуры за считанные минуты. Это не только предотвращает изменение вкуса из‑за остаточного тепла, но и делает скорлупу арахиса хрустящей, подготавливая её к эффективной очистке на следующем этапе.

Он служит важным компонентом для обеспечения непрерывной работы поточной линии и повышения общей эффективности.

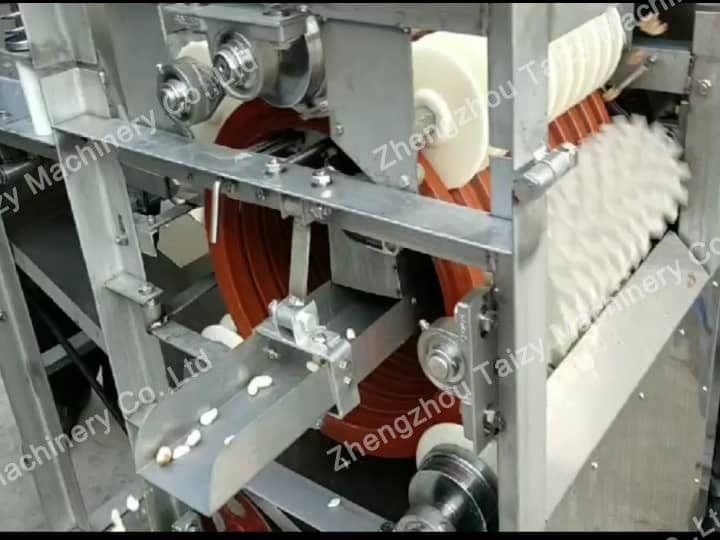

Машина для очистки арахиса

Красноватая кожура арахиса имеет лёгкую горечь, которая может ухудшить гладкую текстуру и золотистый оттенок арахисового масла.

Чистая ли текстура и внешний вид вашего арахисового масла?

Это оборудование использует сочетание принципов разминания и всасывания воздуха для удаления красноватой кожуры с исключительной эффективностью (уровень очистки >96%), при этом сохраняя целостность ядра арахиса.

Чистое, свободное от примесей сырьё — основа для изготовления премиального арахисового масла.

Машина для измельчения арахисового масла

This peanut butter grinding machine directly determines the final texture of peanut butter—whether it’s coarse or smooth.

Насколько гладким может быть арахисовое масло?

Мы используем высокоточный коллоидный меланжер. Его суть — в чрезвычайно малом, регулируемом зазоре между статором и ротором. По мере прохождения ядра арахиса через этот зазор они подвергаются сильным сдвиговым силам, трению и высокочастотной вибрации, мгновенно превращаясь в исключительно тонкую, гладкую пасту.

Вы можете легко регулировать степень измельчения в соответствии с требованием рынка, производя продукты с различной текстурой — от с кусочками до шелковисто-гладких.

Резервуар для смешивания и охлаждения

Чистое арахисовое масло — лишь основа; рынок требует более разнообразной продукции. В то же время свежеизмельчённое арахисовое масло горячее и требует охлаждения для стабилизации.

Как придать продукту вкус? Как обеспечить стабильность продукта?

Резервуар для смешивания: оснащён мешалкой, здесь можно удобно добавлять сахар, соль, стабилизаторы или другие ароматические компоненты, идеально и равномерно смешивая их с арахисовым маслом.

Охлаждающий резервуар: быстро снижает температуру арахисового масла с помощью циркулирующей в рубашке охлаждающей воды. Это стабилизирует структуру продукта, продлевает срок годности и обеспечивает оптимальную вязкость для фасовки.

Машина для наполнения арахисового масла

Заключительный этап производства определяет эффективность упаковки и стандарты гигиены.

Какова скорость упаковки? Точные ли измерения?

Использование поршневых или шнековых дозаторов объёма позволяет точно установить каждый объём фасовки в зависимости от размера бутылки с минимальной погрешностью. Весь процесс автоматизирован, гигиеничен и быстр, что существенно снижает затраты на рабочую силу и потери продукта.

Taizy линия производства арахисового масла на продажу

Полная линия по производству арахисового масла — это не просто набор машин, а тщательно продуманная система, обеспечивающая качество конечного продукта.

От начального этапа обжарки, определяющего вкус, до основного процесса помола, формирующего текстуру, и, наконец, этапа фасовки, задающего эффективность — каждый этап незаменим.

Хотите настроить индивидуальную линию по производству арахисового масла в соответствии с вашим объёмом и бюджетом? Свяжитесь с нашими техническими консультантами сегодня для бесплатной индивидуальной консультации и персонального коммерческого предложения!