The dry peanut peeling machine is a professional nut processing equipment designed for fast and efficient removal of red skins from roasted peanuts, with a stable processing capacity ranging from 200 to 1000 kg/h.

By adopting advanced friction peeling technology and air separation systems, this groundnut dry peeling machine ensures a high peeling rate, low breakage, and clean finished kernels, making it ideal for peanut butter factories, roasted peanut snack plants, and nut ingredient processors.

Dry Type Peanuts Peeling Machine Video

Principio de funcionamiento de la máquina peladora de maní seco

The peanut dry skin removing machine works based on friction peeling and pneumatic separation:

- Roasted peanuts are fed into the peeling chamber

- High-speed friction rollers rub off the red skins

- Peanut kernels and skins are separated by airflow

- Clean kernels are discharged continuously

This process ensures:

- High peeling efficiency

- Minimal kernel breakage

- Stable and continuous operation

Parameters of the Roasted Peanut Red Skin Removing Machine

| Modelo | Capacidad (kg/h) | Potencia del motor eléctrico (kw) | Admirador Potencia (kilovatios) | Voltaje(v) | tasa de trilla (%) | Frecuencia (HZ) | Dimensión (mm) |

| TP-1 | 200-300 | 0.55 | 0.37 | 380/220 | ≥98 | 50 | 1100*400*1100 |

| TP-2 | 400-500 | 0.55*2 | 0.37 | 380/220 | ≥98 | 50 | 1100*700*1100 |

| TP-3 | 600-800 | 0.55*3 | 0.37 | 380/220 | ≥98 | 50 | 1100*1000*1100 |

| TP-4 | 800-1000 | 0.55*4 | 0.37 | 380/220 | ≥98 | 50 | 1100*1400*1100 |

Applications of Peanut Dry Peeling Machine

The peanut dry peeling machine is widely used in:

- Peanut butter production lines

- Roasted peanut snack processing plants

- Peanut candy and brittle production lines

- Peanut paste and sauce manufacturing

- Nut ingredient processing workshops

It is suitable for blanched peanuts, roasted peanuts, and dry peanuts, ensuring smooth downstream processing and premium product quality.

Especialidades de la máquina peladora de maní tostado

High Peeling Efficiency

- Peeling rate ≥ 96%

- Stable skin removal performance

Low Kernel Breakage

- Controlled friction strength

- Adjustable peeling clearance

Continuous Operation Design

- Suitable for industrial-scale production

- Supports long-hour operation

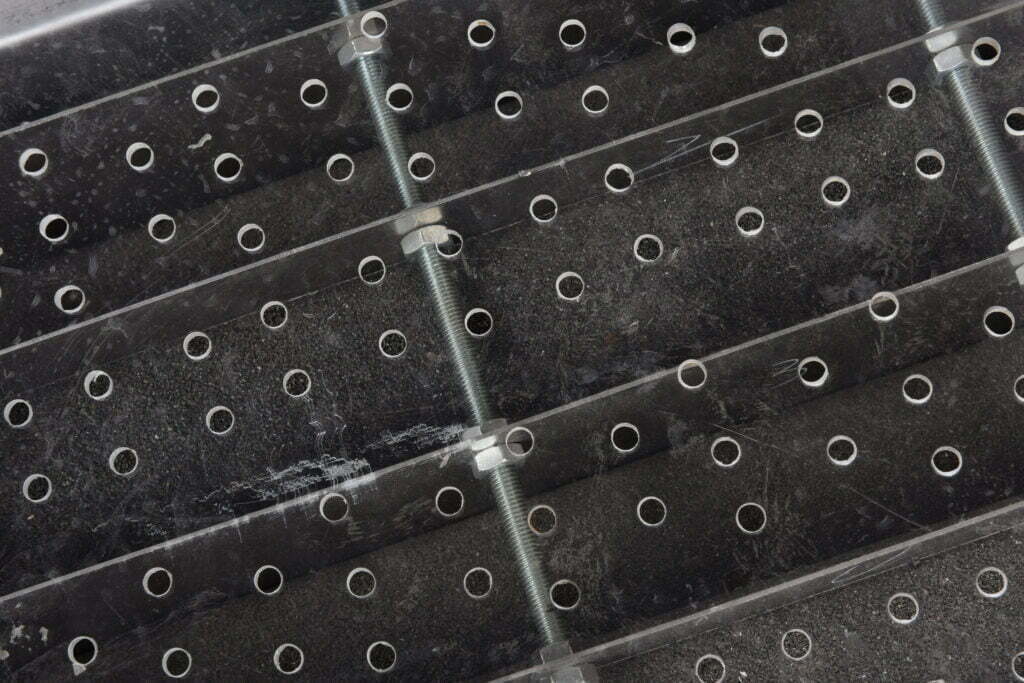

Compact & Durable Structure

- Space-saving layout

- Industrial-grade components for long service life

Advantages of Using a Peanut Dry Peeling Machine

Compared with traditional manual peeling or wet peeling methods, the peanut dry peeling machine offers:

- No water consumption

- No wastewater discharge

- Cleaner processing environment

- Lower operating cost

- Better kernel color and appearance

This makes it an ideal solution for export-grade peanut processing plants.

FAQs

Is this machine suitable for raw peanuts?

No. The peanuts must be roasted or dried before dry peeling.

What is the peeling efficiency?

The peeling rate is ≥96%, depending on the peanut variety and roasting conditions.

Can the machine be used in peanut butter production lines?

Yes. It is widely used before grinding to improve peanut butter color and flavor.

Can capacity be customized?

Yes. We provide different models from 200 kg/h to 1000 kg/h, and higher capacities are available upon request.

Contáctenos

If you are planning to build or upgrade a peanut processing line, our peanut dry peeling machine offers a reliable and cost-effective solution.

Contact us today for technical details, machine configuration, and project consultation.

Related Production

We also provide pre-processing equipment for dry-peeling peanut machines: peanut roasters. This is an indispensable machine for dry-peeling peanuts.