Задумывались ли вы, как в фабриках делают эти вкусные, хрустящие, хрустящие арахисы? За каждым идеально покрытым арахисом стоит полноценная линия производства хрустящего арахиса — высоко автоматизированная система, превращающая сырой арахис в готовый к употреблению, продаваемый продукт.

Давайте подробнее рассмотрим основное оборудование и принципы работы этой линии, чтобы понять, как обрабатывается хрустящий арахис от начала до конца.

Обзор линии производства хрустящего арахиса

Эта линия объединяет несколько машин — от обжарки и очистки до покрытия, жарки и приправления — обеспечивая стабильное качество, высокую эффективность и минимальные трудозатраты.

Линия производства хрустящего арахиса предназначена для массового производства покрытого арахиса, популярной закуски в Азии, Ближнем Востоке, России и за их пределами.

Процесс работы линии по обработке хрустящего арахиса

Обжарка — снижение влажности и активация аромата

Процесс начинается с машины для обжарки арахиса, которая равномерно нагревает сырой арахис с помощью циркуляции горячего воздуха. Этот шаг уменьшает содержание влаги, усиливает аромат и подготавливает арахис к более легкой очистке.

Температуру и время можно точно контролировать для достижения равномерных результатов обжарки.

Очистка — удаление красной кожи

После обжарки арахис подается в машину для очистки, где резиновые ролики или трение лезвий аккуратно удаляют внешнюю красную кожу. Очистка делает арахис чистым и гладким, готовым к покрытию.

Автоматическая очистка обеспечивает высокую эффективность и низкий уровень повреждений.

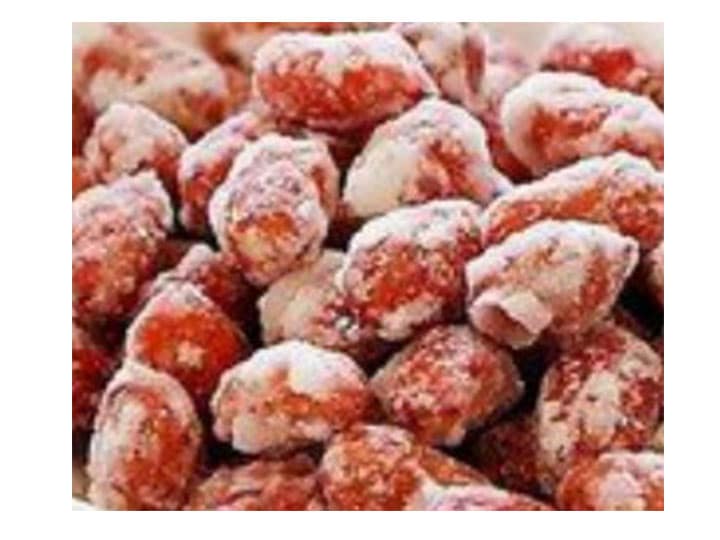

Покрытие — создание хрустящей оболочки

Машина для покрытия арахиса (также известная как арахисовая покрывальная машина) — ключ к формированию характерного хрустящего слоя. Арахис вращается в барабане, пока равномерно не распыляется смесь из муки, крахмала и специй.

Слой за слоем покрытие накапливается, пока каждый арахис не будет идеально покрыт. Этот этап определяет текстуру и хрусткость конечного продукта.

Колебательное обжаривание — совершенствование текстуры

Затем покрытый арахис попадает в качающийся обжарочный шкаф, который использует непрерывный горячий воздух для запекания поверхности до золотистого и хрустящего состояния. Колебательное движение обеспечивает равномерное нагревание каждого арахиса, предотвращая пригорание или неравномерное окрашивание.

Этот этап закрепляет хрустящую текстуру, которая определяет высокое качество покрытого арахиса.

Охлаждение — стабилизация структуры

После обжарки арахис должен быстро остывать, чтобы сохранить форму и предотвратить размокание. Охлаждающая тележка или конвейер продувают холодным воздухом для равномерного снижения температуры, что улучшает стабильность хранения и сохраняет хрусткость.

Приправление — усиление вкуса

Охлажденный арахис перемещается в восьмиугольную машину для приправления, где равномерно распределяются порошки с ароматизаторами (например, барбекю, мед, острый или сыр). Восьмиугольный дизайн обеспечивает мягкое вращение всех арахисов, позволяя приправе идеально прилипать к поверхности.

Упаковка — финальная презентация

Наконец, ароматизированный арахис упаковывается с помощью автоматической машины для гранулированной упаковки. Это оборудование обеспечивает точное взвешивание, заполнение и запайку — гарантируя свежесть, гигиену и привлекательный внешний вид каждой упаковки для розничных продаж.

Почему выбирают нашу линию обработки арахиса?

Наша компания предоставляет комплексные решения для обработки хрустящего арахиса, включая проектирование, установку и обучение. Все машины изготовлены из нержавеющей стали пищевого качества, что обеспечивает гигиену, долговечность и соответствие международным стандартам безопасности.

Мы предлагаем:

- Пользовательские мощности производства (100–2000 кг/ч)

- Энергосберегающие системы нагрева (газ/электричество)

- Легкое обслуживание и интеллектуальные панели управления

Преимущества завода по производству хрустящего арахиса

- Полностью автоматическая операция: минимальный труд населения

- Единообразный контроль качества: постоянные результаты обжарки и покрытия

- Энергоэффективный дизайн: сниженное потребление топлива и электроэнергии

- Широкое применение: подходит для жареных орехов в оболочке, зеленого горошка, бобов и других закусок

- Настраиваемая мощность: от небольших фабрик до крупного промышленного производства

Рыночный потенциал и прибыльность

Хрустящий арахис — один из самых прибыльных продуктов быстрого питания во всем мире благодаря длительному сроку хранения, низким затратам на производство и сильному спросу со стороны потребителей. Рынки в России, Индонезии, Нигерии и Ближнем Востоке показывают растущий интерес к закускам на основе арахиса.

Инвестируя в линию производства хрустящего арахиса, вы можете быстро создать прибыльный бизнес по производству закусок с коротким сроком окупаемости и стабильным спросом на рынке.

Заключение

Линия производства хрустящего арахиса сочетает автоматизацию, эффективность и стабильность для поставки высококачественных закусок с сильным рыночным спросом. От обжарки и очистки до покрытия и упаковки — каждый этап строго контролируется для обеспечения превосходного вкуса и текстуры.

Если вы планируете войти в индустрию обработки закусок, инвестиции в современную линию для покрытия и обжарки арахиса — ваш лучший первый шаг к успеху.

Свяжитесь с нами сегодня для получения подробных коммерческих предложений и индивидуальных решений по производству хрустящего арахиса, чтобы уверенно развивать ваш бизнес по производству продуктов питания.