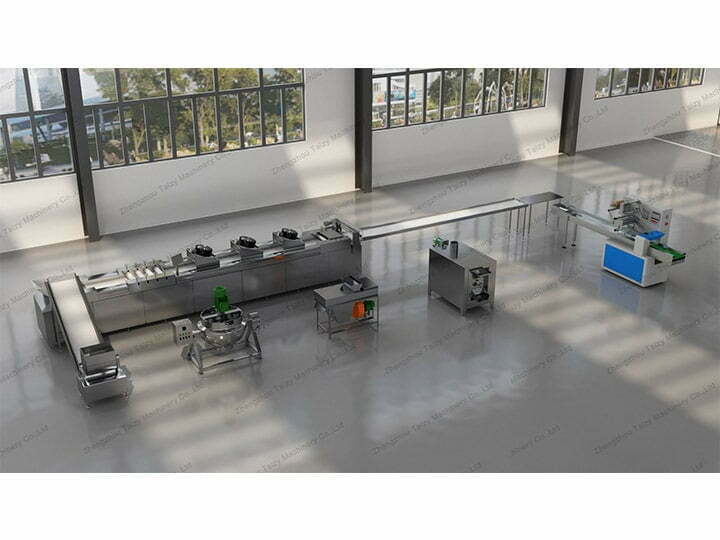

An automatic peanut brittle machine is used to produce candied roasted peanut snacks. The peanut candy production line mainly consists of 6 machines: a peanut roaster, a peanut peeler, a sugar melting machine, a peanut brittle forming and cutting machine, a peanut brittle mixing machine, and a peanut candy packing machine.

The production capacity of the peanut candy production line ranges from 50 to 2000 kg per hour.

땅콩 사탕 생산 라인의 장점

- 고도로 자동화 및 노동 절감

- 제품의 크기와 모양을 균일하고 조절 가능

- 안정적이고 연속적인 작동 및 높은 생산성

- 조작 및 유지 관리가 용이

- 광범위한 적용. 견과류나 씨가 들어간 다양한 설탕 과자에 적합

- 맞춤형 서비스 이용 가능.

Video of the peanut candy cutting machine

땅콩 사탕 바 생산 라인에 포함된 기계는 무엇인가요?

땅콩 설탕 연자 가공 라인은 주로 땅콩 로스터, 땅콩 껍질 벗김 기계, 설탕 용융 기계, 땅콩 설탕 연자 형성 및 절단 기계, 땅콩 사탕 혼합 기계, 땅콩 사탕 포장 기계, 보조 설비를 포함합니다.

1. 땅콩 로스터 기계

The peanut roaster machine is designed to roast peanuts and other nuts or beans, like almonds, cashew nuts, walnuts, chestnuts, sesame seeds, cocoa beans, etc. The advanced drum structure can enable the machine to heat materials evenly and efficiently, with an output of up to 1000kg/h.

2. 땅콩 껍질 벗기 기계

The roasted peanut peeling machine is used to remove the red skins of peanut kernels. It has a high peeling rate and a low breakage rate. The output can be from 200-1000kg per hour.

3. 증기 주거형 냄비

To make peanut candy, syrup is an essential ingredient. A steam-jacketed kettle, also known as a syrup cooking pot, is used to melt sugar for making syrup. It has a double-layer structure with inner and outer spherical pot bodies.

The sugar melting pot has the characteristics of a large heating area, uniform heating, high thermal efficiency, various heating methods, easy operation, and a tilting function.

The general structure contains a mixing rod, cover, pot body, motor, thermometer, hand wheel, control cabinet, etc. The thickness of the pot is 3mm, and the popular volume ranges from 100 to 600L. The finished product can be discharged easily.

The sugar melting pot is widely used in the processing of all kinds of food, and can also meet the needs of large restaurants or canteens for cooking sauce, soup, stew, porridge, and so on.

FAQ

믹싱 기구 없이 뚜껑을 추가할 수 있나요?

네

믹싱 모터를 110V로 교체할 수 있나요?

예.

가열 소스는 무엇입니까?

Electricity, natural gas, liquefied gas, biogas, and steam.

100L 전기 가열 모델은 열전달 오일이 얼마나 필요한가요?

약 40킬로그램.

기계 재료는 무엇입니까?

304 등급 스테인리스 스틸. 맞춤 가능.

4. 땅콩 설탕 연자 혼합 기계

A mixing machine is used to mix the syrup with other materials, especially nuts and seeds, like peanuts, cashew nuts, almonds, walnuts, sesame seeds, sunflower seeds, etc.

믹서 기계는 보온 효과, 온도 제어 시스템, 부식 저항성, 고온 저항성, 비착착성 등의 특징이 있습니다. 또한 제품 배출이 편리합니다.

Technical data of the mixing machine

| 모델 | TZ-100 | TZ-150 | TZ-200 |

| 전압 | 380V/50hz | 380V/50hz | 380V/50hz |

| 전력 | 1.1kw | 1.1kw | 2.5kw |

| 크기 | 700*800*1200mm | 700*500*1400mm | 960*600*1200mm |

| 용량 | 10kg/배치 | 15kg/배치 | 50kg/batch |

5. 상승 컨베이어

The lifting conveyor is to lift and send the material processed by the mixing machine to the automatic cutting machine. The surface is stainless steel, and the conveyor belt material is PVC. The general size is 2500*820*1080mm.

6. Peanut brittle forming, cutting, and cooling machine

The peanut brittle machine integrates the functions of mixing, forming, cooling, and cutting. It applies to a wide variety of snack foods, like peanut candy, puffed rice candy, cereal bar, sesame candy, granola bar, energy bar, protein bar, chikki, and caramel treats etc.

땅콩 설탕 연자 형성 및 절단 기계은 땅콩 사탕 생산 라인의 중요한 부분입니다. 땅콩 사탕을 직사각형, 정사각형, 원형 또는 기타 형상으로 성형할 수 있습니다.

Highlights of the peanut brittle machine

- 다중 및 통합 기능.

The peanut brittle forming and cutting machine firstly stirs the raw materials, and its pressing roller presses sticky raw materials into a flat shape. Then, the 3 fans immediately cool the peanut candy for a better cutting effect in the following procedure.

The peanut brittle machine has a cross cutter and several vertical cutters to cut the whole materials into expected sizes.

- 가변 가능한 제품 크기

The conveyor belt’s width is 560mm. A cross cutter and a set of vertical blades cut the materials on the conveyor into different lengths and widths. The speed of the conveyor is changeable to cut the materials into different lengths.

The width of the material depends on the number of vertical blades, which can be customized based on special needs. The thickness of the raw material is adjustable by using handwheels on both sides to change the height of the rollers.

Besides, we have another type of peanut brittle forming machine, called a rotary table forming machine. It has various molds that can form the materials into round, cylindrical, spherical, or other shapes.

- 위생적이고 내구성 있음

컨베이어 벨트 재질은 PVC이며 기계는 스테인리스로 만들어집니다. 땅콩 설탕 연자 기계는 위생적이며 식품 안전 표준을 충족합니다.

매개변수

| 모델 | TZ-68 | 냉각 컨베이어 |

| 전력 | 2.5kw | 0.37kw |

| 모터 | 380V, 50hz | 380V/220V |

| 크기 | 6800*1000*1200mm | 5000*1000*800mm |

| 벨트 폭 | 560mm | |

| 중량 | 1000kg | |

| 용량 | 300-400kg/h |

7. 땅콩 사탕 포장 기계

The final step of the peanut candy production line is the packaging of the final products. Our pillow-type packing machine is suitable for packing various foods and is widely applied in the food processing lines. The packing speed is 50-300pcs/min.

관련 기사

수출 사례

FAQs

What products can this production line make?

Peanut brittle, sesame brittle, nut bars, cereal bars, and other sugar-coated snack bars.

What is the production capacity?

50–2000 kg/h, depending on line size and cooking capacity.

What is the standard size of the final peanut brittle?

Length, width, and thickness are adjustable. Common sizes: 10–20 mm thick and customizable lengths.

Is the shape uniform after cutting?

Yes. The automatic cutting machine ensures precise, clean, and consistent bar sizes.

Can the line process other nuts besides peanuts?

Yes. Almonds, cashews, sunflower seeds, sesame seeds, mixed nuts, etc.

Do you offer installation and after-sales service?

Yes. We provide layout design, operation training, online installation guidance, and spare parts support.

문의하십시오!

For more details about our peanut brittle machine, please contact us directly!